Note: An updated tutorial was released in 2020: CLICK THIS LINK to view that version

“Instrumentation is a central facet of student, amateur and professional participation in science. STEM education, recruitment of scientists and experimental research are thus all hampered by lack of access to appropriate scientific hardware. Access restrictions occur because of: 1) lack of capital to purchase or maintain high-cost equipment, and/or 2) the nature of proprietary ‘black box’ instrumentation, which cannot be fully inspected, understood or customised…

“Instrumentation is a central facet of student, amateur and professional participation in science. STEM education, recruitment of scientists and experimental research are thus all hampered by lack of access to appropriate scientific hardware. Access restrictions occur because of: 1) lack of capital to purchase or maintain high-cost equipment, and/or 2) the nature of proprietary ‘black box’ instrumentation, which cannot be fully inspected, understood or customised…

…In addition to reducing opportunities for people to engage with science, this lack of access to appropriate hardware restricts scientist’s creativity in experimental designs.”

From: Journal of Open Hardware

Expanding Equitable Access to Experimental Research and STEM Education

by Supporting Open Source Hardware Development

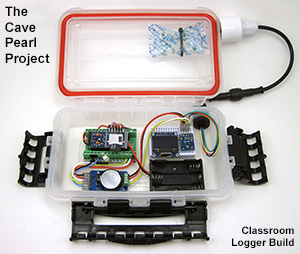

Last year’s intense deployment schedule focused on getting more sensors into the field, which left little time for development of new approaches to the logger itself. Now that everything is settling into the school term routine, it’s time to update the “classroom edition” of the Cave Pearl Logger with feedback from three years in the trenches:

The 2016 build achieved it’s goal reducing construction time, but it was low on important skills like soldering. Limited lab time meant that something had to give if we want students to “pay the iron price” for their data, so we’ve added a pre-made enclosure box. Though it’s not as robust as the PVC housings, it provides more room inside the housing. Past student projects have required things like 555’s, ADS1115 modules, display screens, etc. and the proto-board will make it easier to integrate those additional components.

|

|||||

|---|---|---|---|---|---|

| Bill of Materials: | $18.35 | ||||

| Plano 3440-10 Waterproof Stowaway Box Usually cheaper at Amazon as “add-on” items. $4.96 at Walmart and there are a selection of larger size boxes in the stowaway series. 6″ Husky storage bins are an alternative option. |

$5.00 | ||||

| 4Pin 24AWG IP65 Black Waterproof Cable Connector OD 4mm Better quality version is available at Adafruit for $2.50 each, wBL-RED-Wht-Yel colors used here for the I2C bus. |

$1.00 | ||||

| M12 IP68 Nylon Cable Gland Adjustable for 3mm-6mm diameter. You need two for the build. Make sure they include O-rings. |

$1.00 | ||||

| 3/4″ Schedule 40 PVC Cap Diameter will depend on the size of your sensor breakout board. Get ones with FLAT ends. |

$1.00 | ||||

| White 170 Tie-Points Prototype Breadboard Available in other colors. |

$0.60 | ||||

| Pro Mini Style clone 3.3v 8mHz Get the ones with A6 & A7 broken out at the back edge of the board. |

$2.20 | ||||

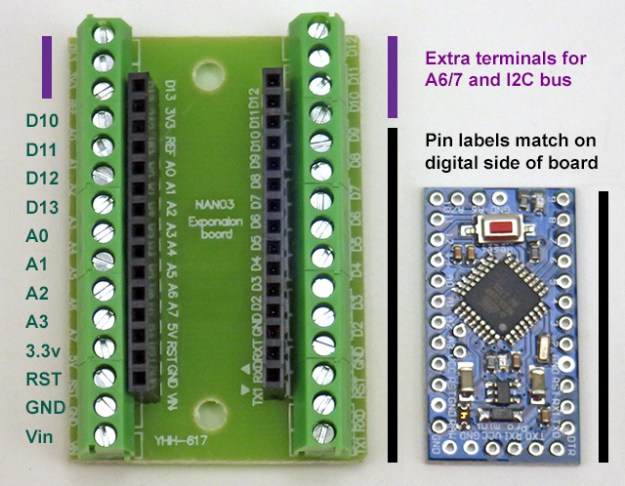

| Nano V1.O Screw Terminal Expansion Board Note: To save time, you can spend an extra $1 for pre-assembled boards by Deek Robot, Keyes, & Gravitech (CHECK: some of them have the GND terminals interconnected) Have a few small flat head screw drivers handy. |

$1.05 | ||||

| DS3231 IIC RTC with 4K AT24C32 EEprom (zs-042) Some ship with CR2032 batteries already installed. These will pop if you don’t disable the charging circuit! |

$1.25 | ||||

| CR2032 lithium battery | $0.40 | ||||

| 4 poles/4 Pin 2.54mm 0.1” PCB Universal Screw Terminal Block Connector These things look “open” when they are “closed”, and you need a very small screw driver to open them. |

$0.40 | ||||

| SPI Mini SD card Module for Arduino AVR Buy the ones with four ‘separate’ pull-up resistors so that you can remove them. |

$0.50 | ||||

| Sandisk or Nokia Micro SD card 256mb-512mb Test used cards from eBay before putting them in service. Older Nokia cards have much lower write currents in the 50-75mA range. This is less than half the current you see on more common larger sized cards. |

$2.00 | ||||

| 3×1.5V AAA Battery Batteries Holder w Wire Leads The Pro Mini regulator will handle battery packs holding from 3 to 8 AA or AAA batteries. If you are using alkaline AAA batteries, changing this to a 4xAA battery holder doubles the run time. |

$0.40 | ||||

| Common Cathode Bright RGB LED 5mm ( & 4k7 limit resistor) |

$0.05 | ||||

| 3M Dside Mounting Tape, 10MΩ resistors & 3MΩ resistors, 22awg silicone wire, header pins, etc… | $0.50 | ||||

| Donation to Arduino.cc If you don’t use a ‘real’ Pro Mini from Sparkfun to build your logger, you should at least consider sending a buck or two back to the mothership to keep the open source hardware movement going…so more cool stuff like this can happen! |

$1.00 | ||||

| Comment: You might need some extra parts to get started: (not included in the total above) | |||||

| 2in1 862D+ Soldering Iron & Hot Air station Combination a combination unit which you can sometimes find as low as $40 on eBay. Or get the Yihua 936 iron alone for about $25. |

$50.00 | ||||

| 3.3V 5V FT232 Module ***Be sure to set the UART module jumpers to 3.3v before using it!*** and you will also need a USB 2.0 A Male to Mini B cable. |

$2.75 | ||||

| Micro SD TF Flash Memory Card Reader Get several, as these things get lost easily. My preferred at the moment is the SanDisk MobileMate SD+ SDDR-103 which can usually be found on the ‘bay for ~$5. |

$1.00 | ||||

Connection Diagram:

This logger uses the same three components described in the paper from 2018, but we now connect those core modules via a screw-terminal expansion shield, rather than soldering them directly to the pins:

COMPONENT PREPARATION

Watch through the videos as a complete set first so you know where you are going, and then use the images below the videos to remind you of the key steps while you do the assembly; It usually goes much faster working from a photo where you can see all the connections at once. The times listed are estimates for people with soldering experience. If you’ve never built a circuit before, then taking 3-4x that long is completely normal. Don’t worry about it – you will be surprised how much faster you get with a little practice!

Screw Terminal board: (~40min) or ( 5min with pre-assembled board)

Don’t forget to measure the values of the resistors before soldering that voltage divider. You will need those values to calculate the battery voltage based on the ADC readings from pin A6.

These screw terminal boards are designed for an Arduino Nano, but if you orient the board to the Tx/Rx pins, the labels on digital side of the shield will be correctly aligned with the Pro Mini:

The most common beginner errors at this stage are crooked headers & not heating the pad/pins long enough for solder to flow properly. This is often because students are trying to use an iron tip that has “gone dry” so the heat is not transferring properly to the pins. You must protect soldering iron tips with fresh solder every time you put it in the stand to prevent oxidation. Tip Tinner can sometimes restore those burnt tips. {Click images for larger versions}

It is better to err on the side of using a little too much heat, because partial connections to the screw terminals will cause you no end of debugging grief later: Cold solder joins can “sort of” work “sometimes”, but cause mysterious voltage drops over those points because they can act like randomly variable resistors in your circuit. Note: This voltage divider uses meg-Ω size resistors and takes >1 second to charge the capacitor when the unit is first powered on – so you can’t take the first battery reading until that much time has passed.

The Pro Mini Board: (~40 min)

~5-10% of the cheap Pro Mini clones from eBay are flaky, and it is quite annoying to discover one of those that after you have assembled a logger. So test your board with the blink sketch before you remove pin13 LED resistor. These limit resistors move around from one manufacturer to the next, so you might have to go hunting for them on your particular board. You also need to remove the RESET switch from the board, or that button will be compressed when you put the SD card adapter in place:

|

|

|

|

|

|

(Note: Credit goes to Brian Davis for the idea of using “extra header pins” when patching to the unused to screw terminals.)

The SD Card Adapter: (~15 min)

This SD card adapter comes with small surface mount pull-up resistors on the MOSI, MISO & SCK (clock) lines (removed from the dashed red line area photo 2 below). The Arduino SDfat library uses SPI mode 0 communication, which sets the SCK line low when the logger is sleeping. This would cause a constant drain (~0.33mA) through the 10k SCK pullup on the module if we did not remove it. I prefer to pull MOSI & MISO high using the internal pull-ups on the Atmel328P processor, so those physical resistors on the breakout board can also be removed. Leave the top-most resistor of the four in place to pull up the unused DAT1 & DAT2 lines. This keeps those unused pins on the SD card from floating, which can draw excess current.

|

|

|

|

|

The SPI connections: RED: 3.3v regulated Grey: Cable select (to D10) Orange: MOSI (to D11) Brown: SClocK (to D13) Purple: MISO (to D12) BLACK: Ground |

|

|

Attach SD adapter & Pro mini to the Screw Terminal Board: (~20 min)

Label the Vcc & GND connections with a colored marker, then insert the Pro Mini into the headers on the screw-terminal shield. Be careful not to bend the pins – especially the “extension” pins at the back of the board. It’s easy to connect the board in the wrong orientation at this step. The voltage divider on the bottom of the screw terminal shield aligns with the ANALOG side of the Promini board.

|

|

Then affix the SD adapter board to the top of the Pro Mini with a slight overhang, so that the jumper wires align with the screw terminals below. Trim the wires about 1cm past the edge of the board to provide enough stripped wire for the terminal connection.

|

|

|

LED on pins D4-D6, & GND. NOTE: Grounding the LED through D3 lets you use the LED as a sensor and support for this is included in the base code. Also see: multiplexing wD9 GND |

The RTC Module: (~15min)

The simplest modification to these DS3231 RTC boards is to remove the charging circuit resistor and power LED limit resistor from the circuit board (the red squares in the first picture). A non-rechargeable CR2032 coin cell battery will supply the RTC with power for many years of operation. Note: The 32K pin is not connected, and does not get a jumper wire. The four screw terminals go on the same side as the battery holder.

|

||

|

|

|

Add an extra layer of foam tape over the smaller 4K eeprom chip, so that the thickness matches the top surface of the DS3231 chip. The RTC board already has 4.7kΩ pull-ups on the SDA (data) and SCL (clock) lines so you will not need to add them to the bus. This module also has a 4.7k pull-up on the SQW alarm line. Adding the screw terminals to the small cascade port on the RTC module is another creative idea from Brian D, but you could just add straight pin headers: If you don’t want to make your own crimp ends, 4-pin JST XH series connectors have a pitch of 2.5 mm which is effectively identical to the 0.1″ pitch of those Dupont pins.

The Plano Stowaway housing: (~10 min)

In these photos, I’ve melted threads into the housing for a pass-through with a cable gland, but that is entirely optional. This trick works with many different housing materials, but it takes a bit of practice to figure out what the right temperature is for any given one. The plastic in the plano boxes melts quite easily, so be gentle with the heat gun. Glands much larger than PG7 (12mm) will not fit in the available space in that corner.

You may need two washers due to the curvature of the box. The cable gland shown above is an M12 x 1.5 IP68 for 3-6mm dia. cables (also desc. as PG7 12mm) |

Strategically placed holes in the clips provide zip-tie locations to secure your logger.

|

|

ASSEMBLING THE LOGGER PLATFORM: (~30 min)

Using double sided tape to hold the parts inside the housing (rather than traditional stand-offs) makes this stage of the build remarkably quick. Adding male Dupont pins allows you to join internal and external wires via the breadboard. Be sure to use wires that are long enough to reach the mini breadboard.

|

|

|

|

Bowing on some boxes can reduce the contact patch on the battery holder, if so try adding another layer of tape, or upgrade to 30LB. |

Connecting external sensors to the housing:

It’s worth mentioning the breadboard contacts are notoriously sensitive to vibration, etc. Once your testing stage is complete, and your prototype is working as it should, bring those sensor wires directly over to the screw terminal connections for a more secure connection. Also remember to put protective tape over any sensor ports that need to remain open before potting those sensor boards in epoxy. Otherwise you might clog the sensor by accidentally letting a drop fall into it.

|

|

|

Your Logger is ready! (~2 to 2.5 hours)

Now you can test your new logger to confirm all the connections are working:

1. Test the LED – Edit & upload the default blink sketch, changing the pin numbers each time to match your RGB LED connections.

2. Scan the I2C bus – with the scanner from the Arduino playgound. The eeprom on the RTC module is at address 0x56 or 57 and the DS3231 should show up at address 0x68. If you don’t see those two devices when you run the scan, there is something wrong with your RTC or the way it’s connected.

3. Test the EEprom on the RTC module – We’ve updated BroHogan’s original code from the playground to this tester script. You may have to change the I2C address at the start of the code based on the numbers shown during your I2C bus scan. The AT24C32 will store 4Kbytes, and has a 32-byte Page Write mode which accommodates the maximum of 30 bytes you can transport the wire libraries I2C coms buffer. Make sure you don’t do eeprom page-writes that pass over the physical page boundaries set by that eeproms 32 byte block size. If you are ready for the added code complexity, buffering data to the eeprom can dramatically cut down on the number of SD card saves, however the eeprom communications are so slow that sometimes it ends up using the same amount of power as simply writing your data directly to the SD card directly.

An alternative parts arrangement for the classroom logger that makes room for a larger 4xAAA battery holder and DUPONT style connectors. It’s easy to move things around to suit your own projects, and rotating the breadboard gives you room for larger battery holders & longer operating times. Note: For most 1.5V alkaline batteries, (voltage-1)*200 will give you the approximate percentage of total capacity remaining.

4. Set the RTC time, and check that the time was set – There are dozens of good Arduino libraries you could use to control the DS3231, and there is a script over at TronixLabs.com that lets you set the clock without a library. The trick with Tronix’s “manual” method is to change the parameters in setDS3231time(second, minute, hour, dayOfWeek, dayOfMonth, month, year); to about 1-2 minutes before the actual time, and then wait to upload that code till about 10-15 seconds before your computers clock reaches that time (to compensate for the compiler delay). Open the serial window immediately after the upload finishes, and when you see the time being displayed, upload the examples>blink sketch to remove the clock setting program from memory – otherwise it will keep resetting the RTC every time the Arduino re-starts. [ Note: hour in 24-hour time, & year with two digits eg: setDS3231time(30,42,21,4,26,11,14); ]

5. Check the SD card is working with Cardinfo – Changing chipSelect = 4; to chipSelect = 10;

Note that this logger requires the SD card to be formatted as fat16, so most 4GB or larger High Density cards will not work. Most loggers only generate 5 Kb of data per year anyway.

These breadboard connections are really vulnerable to vibration, so for quick back-yard tests of a rough prototype I sometimes add a tiny spot of hot-melt glue to stabilize the components. Breadboards add about 2-4pF of capacitance for side by side rows so the rule of thumb is you shouldn’t run protoboard circuits much faster than 1 MHz.

6. Check the sleep current – With an SD card inserted in the logger, upload this Pro Mini datalogger starter script with no changes (note: that code requires you to install three libraries as well). Then connect an ammeter between the positive battery connection and the Vin screw terminal (you will need an extra wire to do this) and run the logger from the AAA or AA battery pack. After the initialization sequence has finished, the reading on the screen (in milliamps) is your loggers sleep current.

AAA cells usually provide about 1000 milliamp-hours of power to their rated 0.8v, but we are only using half of that from alkaline batteries with a regulator input cutoff up at 3.6v. So dividing 500 by your loggers sleep current gives you a rough estimate of your loggers operating life (in hours). For a more accurate estimate, you can use one of the Battery Life Calculators on the web with 250ms @5mA for your sample time. Changing the power supply to 4xAAA cells lets you bring alkalines down to 0.9v/cell, extracting almost the entire 1000 mAh. Lithium AAAs deliver almost their entire capacity above 1.2v/cell so 3xAAA lithiums yield almost 1000 mAh capacity even with the 3.6v input cut-off.

Thermal response of 3x AAA’s (mV left axis) vs Temp (°C right axis) in the standard voltage-regulated classroom build running the starter code from Github. The 90mv drops caused by SD card “controller housekeeping events” at 20°C increase to ~220mV as temps near -15°C. These periodic high drain (100-200mA) events would likely trigger the low-voltage shutdown before anything else in the loggers normal duty cycle. (Note: Battery readings taken AFTER SD save, Sample interval: 1 min, sleep current for this test unit: 0.22mA )

Its worth noting that the starter program we’ve provided captures an ambient temperature record from the RTC in 0.25°C increments (example right). New sensor readings can be added to the log file by inserting:

file.print(YourSensorVariableName);

followed by a separator file.print(“,”);

in the main loop before you close the datafile on the SD card. Then change the text in the dataCollumnLabels[] declaration to add headers to match your new data. This starter script automatically generates required data files on the SD card at startup, and tracks the rail voltage for those adventurous enough to run without a regulator. SD memory is electrically more complex than the Pro Mini processor, with some using a 32 bit arm core.

Once you have your logger running, you might want to review our tutorial on adding sensors to your data logger. And after that you’ll find a few more advanced I2C sensor guides on this site as well (…and the list is constantly growing) We’ve also developed methods to add 5110 LCD & OLED screens to the Cave Pearl Loggers using the fewest system resources. These screens are easily accommodated on the proto-board in this build.

For people wanting to take their skills farther, you can explore the gritty details of how we optimize these loggers for multi-year deployments in the 2018 Sensors article (free to download). The research loggers are a more challenging build, that fits inside an underwater housing made from PVC pipe.

Addendum: Power Management (Optional)

On the standard build described above, the Pro-Mini’s MIC5205 power regulator should deliver sleep currents below 0.25 mA (Pro Mini ~0.05 mA + sleeping SDcard ~0.05-0.09 mA + RTC ~0.09 mA). That should reach several months operation on 3 AAA cells before the batteries reach the regulators 3.4v input cut-off. I usually have regulated loggers go into shutdown mode at ~3.6v to reduce the chance of leaks, because alkaline batteries often spill their guts when they reach 1v/cell.

There are a couple of relatively simple modifications to the basic logger that more than double the operational time – but they both come with important implications you should understand fully before adding them to your project. The RTC mod is relatively safe, but running a datalogger from a raw battery supply is not for the faint of heart.

2) Remove the regulator: few LDO’s have reverse current protection & most regs leach 30-90 uA if the voltage on output line is higher than on their input |

The DS3231 RTC was designed to handle power supply failures by switching over to the backup coin-cell battery, and it enters a special 3uA “timekeeping mode” to use less power in that situation. However the chip is still fully capable of generating alarms (provided you set the Battery-Backed Square-Wave Enable bit of CONTROL_REG 0x0E to 1) , and of responding to the I2C bus at 400 mHz. So if you cut the main power leg on the RTC you reduce the loggers sleep current by almost 0.1mA (~40%). The trade-off is that your loggers operation is now entirely dependent on the 200mAh CR2032 coincell to keep the clock delivering wake-up alarms when you are also asking it to deal with pulsed loads in the 80 uA range every time you communicate over the I2C bus. The RTC also can not generate temp-corrected frequency outputs on the 32kHz pin when operating from the coin cell.

Here drops of hot glue secure the RTC coin cell battery against accidental resets. It’s worth noting that even with this precaution, we still see 1-2 units out of 10 loose their time when they have to be transported in airline luggage.

Another quid pro quo here is that coin-cell holders occasionally lose contact very briefly under vibration, so if you cut the Vcc input leg – add a 0.1 μF capacitor (ceramic 104) across the coin-cell holder pins. That will give you about 80 ms coverage, which should be longer than the holder will lose contact. Otherwise a hard bump can reset the RTC back to its Jan 01 2000 default. The wake-up alarms usually continue after that kind of reset, however fixing an entire years worth of time series data based on your field notes is a pain in the backside. Real world installations often involve this kind of rough handling, so I prefer a more advanced RTC modification that keeps two power lines feeding the RTC. But for more “gentle” deployments, simply cutting the chip’s vcc leg & adding a couple of drops of hot glue OK. Write the installation date on the coin cell with a black marker. I do this to all of my batteries now…

For loads in the 0.1mA range, the MIC5205 is less than 60% efficient. So the other modification is to remove the voltage regulator and run the entire system from 2x LITHIUM AA batteries. Lithium batteries (like the Energizer L91) have two characteristics that make them well suited to this approach: 1) they have an extremely flat discharge curve, yielding >75% of their power before the voltage falls below 1.5v/cell on the lower plateau and 2) a pair of brand new lithium cells gives a combined voltage right at 3.6 volts. If you look at any of the SD card manufacturers’ specifications, they all specify a voltage range of 2.7v to 3.6v. At 8 MHz the ATmega328P processor on the ProMini supports voltage levels between 2.7 V and 5.5 V. Both of these ranges overlap beautifully with the lithium cell’s discharge curve. If you are using ratio-metric analog circuits then the voltage fluctuation over time will not affect your readings, but if you need absolute measurements then use the internal voltage reference as Aref. Digital sensor levels are based on a percentage of Vcc, so they are relatively insensitive to voltage variations.

For loads in the 0.1mA range, the MIC5205 is less than 60% efficient. So the other modification is to remove the voltage regulator and run the entire system from 2x LITHIUM AA batteries. Lithium batteries (like the Energizer L91) have two characteristics that make them well suited to this approach: 1) they have an extremely flat discharge curve, yielding >75% of their power before the voltage falls below 1.5v/cell on the lower plateau and 2) a pair of brand new lithium cells gives a combined voltage right at 3.6 volts. If you look at any of the SD card manufacturers’ specifications, they all specify a voltage range of 2.7v to 3.6v. At 8 MHz the ATmega328P processor on the ProMini supports voltage levels between 2.7 V and 5.5 V. Both of these ranges overlap beautifully with the lithium cell’s discharge curve. If you are using ratio-metric analog circuits then the voltage fluctuation over time will not affect your readings, but if you need absolute measurements then use the internal voltage reference as Aref. Digital sensor levels are based on a percentage of Vcc, so they are relatively insensitive to voltage variations.

Here I’ve done both modifications to the basic build, and brought the sleep current (with no sensors) from an unmodified starting point of 228μA, down to 80μA. Most of that remaining power is due to the sleeping SD card, since the Pro Mini only draws about 5μA in deep sleep mode. Using only 1/2 of the 3000 mAh capacity of a typical AA Lithium pack would keep a logger that sleeps at 0.1mA alive for more than a year, and my rough estimate is that the RTC mod will get you at least twice that much time from a new Cr2032 cell – with a typical 5-15 minute sampling interval. [NOTE: I’m using an EEVblog uCurrent here to display the μA sleep current on a DVM as milivolts. It’s an exceedingly useful tool that lets you read sleep currents into the nano-amp range without adding the burden voltage you’d see from putting your meter directly into the circuit ]

(NOTE: that Atmel provides no specs on the long term stability of the bandgap ref. and even OpenEnergy no longer uses the internal 1.1vref because v.regulators offer more long-term stability. ALSO NOTE that genuine Sparkfun ProMini’s have an SJ1 jumper that lets you disconnect the reg simply by de-soldering a pad on top of the board , but clones rarely have that feature.)

Unlike alkaline batteries, lithium cells have very little voltage droop with brief loads below 100mA, but it’s still a good idea to protect your SD card from potentially data corrupting brief low voltage spikes with a capacitor. The formula for figuring out how much the voltage across a capacitor will drop is ΔV = current(A)*time(sec)/C(farads) – but you need to decide how much your supply can drop to know how big to make the capacitor.

Adding a 47uF (or larger) on the microSD rails should keep the shortest transients under control, and once the system reg. has been removed running a jumper between Vcc & Raw recruits the orphan (10uF tantalum) capacitor from the input side of the (now removed) regulator. Always check the supply voltage before the data saving begins and perform a low voltage shutdown when the lithium pack reaches 2875mv. (ie: at least 150mv above the SD’s 2.7v safe writing minimum). Generate a new data file every couple of weeks so only the last one is vulnerable during the write process.

2x LITHIUM AA’s (mV left axis) vs Temp (°C right axis) supplying power to an unregulated build running the same code from Github. The key observation is that the initial 50mv supply voltage variation recorded at 22°C increases ~100mV at temps near -15°C. For Lithium chemistry batteries with flat discharge curves, the voltage-drop under load is often a better indicator of the remaining battery capacity than the cell voltage. (Readings taken AFTER SD CARD SAVE, Sampling every 1 min, overall sleep current 0.17mA Note: the 200mv baseline drop on the cells is slightly exaggerated here because low temps increase the bandgap slightly)

Of course everything has a price, and removing the regulator means you’ve not only lost your reverse voltage protection – you also need to think about how all the components in your system will respond to a decreasing supply voltage over time. Ratiometric analog circuits using the rail as Aref handle this well, but even if you want to use the 1.1v bandgap ref – you already know what the rail voltage is, so you can easily throw a compensation factor into the calculation. The real problem is that when 2.7 – 3.6v is listed on the spec sheet for a digital sensor – that’s no guarantee the readings will be consistent when the supply voltage changes. You could have very different error percentages at the high & low end and ambient temperature fluctuations could push your batteries through significant voltage changes every single day (lithium cells are more resistant to this than alkaline). According to Murata the 8Mhz system clock will remain stable: “Unlike RC or LC circuits, ceramic resonators use mechanical resonance. This means it is not basically affected by external circuits or by the fluctuation of the supply voltage.”

Testing is the only way to find out if your sensors can handle the variation, and if you don’t have time for that it might be worth keeping that voltage regulator on board despite the reduced lifespan. For field units, I usually replace the MIC5205 with a more efficient MCP1700 regulator because I want all the data consistency I can get. Another thing to keep in mind when you are hoping for a really low-power build is leakage currents through leftover flux – it’s always worth the time to get your parts squeaky-clean during construction.

Addendum 2019-02-21:

A teacher friend asked us for a version that was less dependent on soldering because they didn’t have the budget for a classroom set of soldering stations. So we’ve worked out a 1 hour “simplified build” of this logger that uses crimped Dupont jumpers to reduce assembly time:

We’ve also added support to the starter code for using the indicator LED as a light sensor, but this requires that you ground the indicator LED’s common cathode through a digital pin (usually D3) , rather than directly to GND as shown in the tutorial above. Also note that the technique relies on the very tiny internal capacitance inside the LED (typically 10 to 15 pF) so you need to connect the LED right to the screw terminals (ie not the breadboard). Then you can gather three-channel light level data like this:

Readings from an RGB LED deployed outside in our back yard on an overcast day with two light snow fall events. The yellow line is from an LDR sensor in the same logger that was over-sampled to 16-bit. In this case the clouds & snow acted as a near perfect light diffuser, but in normal weather I’d have placed a thin white teflon sheet over the LED sensor to smooth out the readings. Adding an IR led to the logger lets you create a transmission-based NDVI variant that discriminates the amount of chlorophyll in plant leaves.

These readings are arbitrary time-based units that are completely dependent on your particular hardware combination and system voltage. If you go down the DIY sensor rabbit-hole, you might want to calibrate against the NOAA observations for your area, which includes hourly data for thousands of stations. The data includes temperature, dew point (from which you can compute relative humidity), wind speed & direction, and you can calculate solar position.

Addendum 2020-08-18:

We’ve found that the seal on some of the Plano boxes needs a little help, or current leakage via surface moisture shorts out the LED light sensor readings. In the worst cases leakage lets in enough water vapour to chew through your desiccant pack in less than a week. A little bead of silicone under the o-ring corrects that problem:

If you already have your logger assembled, try to find a better quality silicone sealant that does not off-gas acetic acid (smells like vinegar) which could harm the circuits. If you are preparing empty boxes before the logger assembly, then any regular bathroom sealant will do provided you give it about a week to finish curing. I usually choose silicone rated for outdoor applications as they have better resistance to breakdown from UV exposure.

Pingback: Pro mini logger project for the classroom – gStore

This looks great, and I hope some classrooms take this up and give you feedback. I like the easy clear case which makes it easy to open, swap cards, and see the status LED (or display). Another nice aspect of those Nano breakout boards is that you can swap out the program in the field… just take out a replacement MiniPro with the updated SW, and swap them. I’m moving back in that direction for my builds (as opposed to completely soldered versions).

I like the idea of the solder less breadboard, but I’ve moved away from that because I’ve had some that were just flaky enough that I was having trouble with consistent SD card communication – obviously not a problem here, but I wondered if you had any problems with I2C or other devices failing occasionally, perhaps because of the solder less breadboard terminals?

Using the lithium cells is interesting too – I recently ran some freezer tests with alkaline cells at -40 °C (yes, our freezer… is colder than it needs to be) and was surprised at how well they handled it, but for weather-balloon based datalogging (something else the very light Cave Pearl style would be excellent for) we always used Energizer lithiums because they handled such low temperatures well (-60 °C being common near the apex of flight). I’d stayed away from them in cave applications because I’m running on the regulated MiniPro boards, and the flat discharge curve would make estimating longevity nearly impossible. I may take another look at that, as the lithiums would give extra capacity for less weight.

Any idea how much capacity you throw away by feeding the regulated MiniPro from four AA’s? I realize the voltage over the regulated voltage isn’t as efficient, but I’m still unclear what the “cost” of such a strategy is. I really need to do some low-voltage testing to make sure the loggers (OK, my code) does a graceful shutdown, but so far I’ve just deployed and hoped (I can pull them in faster). This last time I did have both deployed loggers expire in the field, and I’m not sure why (yet), but I was running them to a low battery state. I think I need the code to note a battery shutdown in the EEPROM so that I know what occurred but I don’t need to worry about corrupting the card.

I’d love to see how these enclosures hold up under long-term deploys. I wouldn’t trust them under water of course, but above the water line environmental monitoring might be interesting. Maybe the next long deployment you do in the field you should take some current and past student-built units, and toss them next to a surface (weather) station. I’ve actually moved to a $4 Tupperware style container. Those have handled 3 months of deployment in fall conditions outdoors here (wind, rain, some snow), and when I swapped out the in-cave units I put them in these lighter containers. They aren’t pressure-proof (which works well in some ways for my deploys… I need ambient pressure measurements) and the weak place in some ways is that cable gland (I’m using a “waterproof” cord relief attachment, which might be highly water resistant for a single round wire, but not for more than one certainly), but I’ve seen no evidence for enough moisture getting in over time to make a difference. We’ll see over time.

As usual, there’s so much here that I can’t claim I’ve taken it all in, but I really like the look and ease of this build (and yes, I realize I have a bias, but still 🙂 ).

“just take out a replacement MiniPro with the updated SW, and swap them”

My only concern is that I might create a flaky connection in the process on those extension pins. I’d want some kind of extra blink code on startup to make sure that the swap worked Ok. I’ve also heard that there is an app now for reprogramming from your cell phone, so perhaps that’s another in-the-field option?

“…other devices failing occasionally, perhaps because of the solder less breadboard terminals?”

SD cards seem to be much more sensitive to this problem – likely because of the complexity of their controllers. I’ve noticed that many cards don’t sleep properly unless you 1) start SPI 2) init the card 3) open a file on the card 4) save some data and 5)close the file on the card. Having to do all that just to get the controller to calm down is excessive. IC sensors usually go into standby mode all by themselves, and often retail their old register settings – so they have less trouble with breadboards. Some still have issues, but most seem handle the connection loss more gracefully. The breadboard is mostly for the dev stage on a project when things are being changed around frequently. Once the students get their code working, they can jumper the sensors directly to the screw terminals.

“Any idea how much capacity you throw away by feeding the regulated MiniPro from four AA’s?”

Very little, however the voltage droop during SD writes becomes extreme if you bring those alkaline cells down to 1v/Cell – and this is the same issue you were concerned about with the rapid drop off at the end of the Lithium lifespans.

My current solution is to keep tabs on the droop with a constantly updated ‘SDsaveVoltageDelta‘ variable

(see: the starter code in Github )

“I think I need the code to note a battery shutdown in the EEPROM”

I’ve been thinking about that too. We’ve had a few loggers go into restart loops when sensors go squirrely. Fortunately there’s been no data lost yet, because we buffer days worth of data in the field unit to the external eeproms like the one on the RTC module. But I did not include the eeprom buffering that we talk about in the Sensors paper in the starter sketch for the classroom logger- it’s a bit of a stretch for coding beginners.

“I’d love to see how these enclosures hold up under long-term deploys.”

We are excited to see the new crop of student builds, hoping that they get a decent amount of time with their final projects outdoors. The seal on the Plano is pretty convincing, but Achilles heel of all plastics is how they respond to UV. And everything cooks if you leave it in the direct sun unless you add insulation.

“…I’d want some kind of extra blink code on startup to make sure that the swap worked Ok.”

True. but what could go wrong? As long as the MiniPro can talk to all the sensors, and the SD card, and the EEPROM, it should be set. In my start up I have the indicator LED blink three times for each I2C sensor it checks followed by a longer colored blink (green for good, red for bad/missing/failed/can’t find), and a quintuple blink followed by a status color for each DS18B20. It also signals with a rotating tricolored pattern an SD card failure of any type. So if I swap and restart, I just watch a series of status checks on the LED. I put this in initially to catch dead or misconnected sensors, but it’s now stock.

“…I’ve also heard that there is an app now for reprogramming from your cell phone, so perhaps that’s another in-the-field option?”

I hadn’t heard that, but that would be a fantastic option – I’d been debating adding a triggerable bluetooth or wifi ability to download data in the field, but if there was something that allowed my to use a smart phone to access things in serial form it would be possible to not only upload new code but offload all the data to a handheld unit.

“…however the voltage droop during SD writes becomes extreme if you bring those alkaline cells down to 1v/Cell…”

So far I’ve just been recording the minimum voltage during a wake cycle (almost always occurs after the SD operations or EEPROM operations) and using that as my “usable battery limit”, but it might be interesting to track the voltage drop. So that’s another thing I should add, as well as the way you track processor up time (I don’t do that… yet).

“…Achilles heel of all plastics is how they respond to UV. And everything cooks if you leave it in the direct sun unless you add insulation.”

In cave this obviously hasn’t been something I’m worried about, but for the weather station I deployed I did. We’ll see how it goes, but I took a simple solution. The logger is in a Tupperware style enclosure, which is then in a wood enclosure (just a 2×6 on top and bottom, separated by a 2×4 along one long side with the other sides open) with a sheet of white plastic (the type used as siding on houses) over the top and curving down over the open side. The result doesn’t have much of a thermal problem (In Indiana… your deployment site obvious has different issues) because while it’s not insulated it is heavily thermally buffered by the thick (but cheap) wood, yet it’s not sealed and allows reasonably good airflow.